Through hole PCB Assembly

Through Hole PCB Assembly

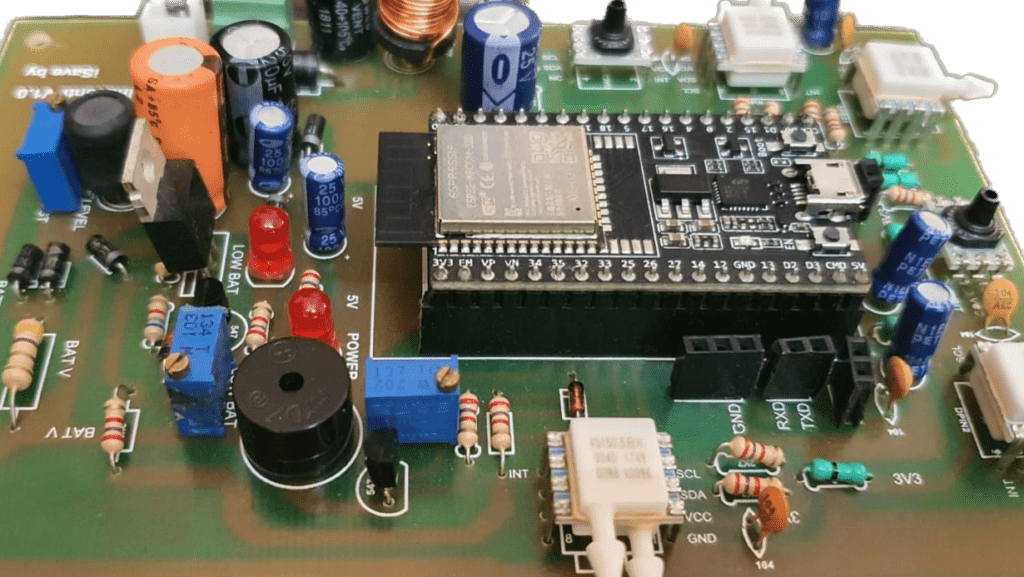

We use manual and automated techniques to satisfy through hole assembly requirements for lead components. This mounting technology uses leads to connect two locations on a circuit board electrically. This process id coined as ‘through hole’ relating to the drilling it involves to insert the lead through the hole and solder components using manual or automated soldering methods. Through hole has a stronger bond between the board and components which increases reliability and enhances durability.

Although SMT assembly is widely used form of assembly these days, through hole mounting technology is more efficient for those equipment that undergo high-stress level operations or at high speeds and extreme temperatures and thus used in aerospace and defence industries. Through hole mounting is a recommended and ideal for military-grade applications given its ability to be resistant to environmental and mechanical stress, withstand in high power and voltages and extreme temperatures.

Advantages of Through-Hole Technology

- More resistant to environmental stress

- Adjust or replace leads manually

- Room for improvement in prototyping

- Rearrange layouts

- Ideal for testing

- Highly reliable and durable

- Strength of bonds

- Ideal for larger components that experience high power and high voltage

Understanding intricacies

Our excellent team of engineers understand the importance of precision, quality control and ruggedness in working with through hole PCB assembly mounting. After designs are approved and milled on the board, our assemblers drill holes and insert leads through them. Before placing and manufacturing the components, they ensure the perfect orientation on the boards, inspect it and finally solder the leads.

Are you looking for flexible options?

build your best connection with us

be the first to get the latest news from ark circuitry!

Please Enter Your Email To Subscribe