In the field of electronics reverse engineering, the art of component analysis holds a pivotal role in unravelling the intricacies of electronic devices and systems. This process involves dissecting and understanding individual components, from integrated circuits to sensors, to reconstruct and enhance their functionality. In this blog post, we’ll delve into the nuances of component analysis in electronics reverse engineering, exploring its methodologies, challenges, and transformative impact on innovation.

The Importance of Component Analysis :

Component analysis serves as the foundation of electronics reverse engineering, offering insights into the inner workings of electronic devices. By dissecting and analyzing individual components, engineers can gain a deeper understanding of their specifications, connections, and functionalities.

Methodologies of Component Analysis :

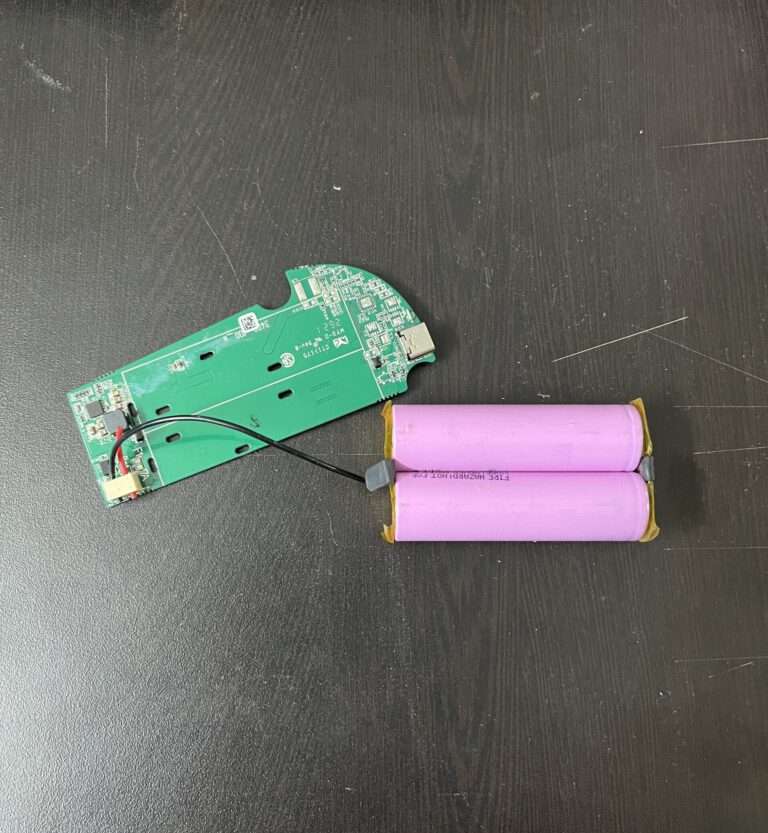

One of the key methodologies in component analysis is non-destructive testing, where engineers use techniques such as X-ray imaging and scanning electron microscopy (SEM) to examine components without damaging them. This allows for detailed inspection of component structures and materials.

Challenges in Component Analysis :

While component analysis is a crucial step in electronics reverse engineering, it comes with its set of challenges. Miniaturization of components, complex circuitry, and proprietary technologies can pose obstacles in accurately analyzing and understanding components.

Tools and Technologies :

Advancements in technology have significantly enhanced component analysis in electronics reverse engineering. High-resolution imaging techniques, such as atomic force microscopy (AFM) and 3D scanning, enable engineers to capture detailed images and measurements of components for precise analysis.

Applications and Use Cases :

The insights gained from component analysis in electronics reverse engineering have broad applications across industries. From optimizing performance in consumer electronics to enhancing functionality in medical devices, the ability to dissect and understand components drives innovation and product development.

Future Trends and Innovations :

Looking ahead, the future of component analysis in electronics reverse engineering is promising. Advancements in machine learning, artificial intelligence, and automated testing are poised to revolutionize the way components are analyzed, accelerating the pace of innovation in the electronics industry.

In conclusion, mastering the art of component analysis in electronics reverse engineering is essential for unlocking innovation, driving technological advancements, and staying ahead in a rapidly evolving industry.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!