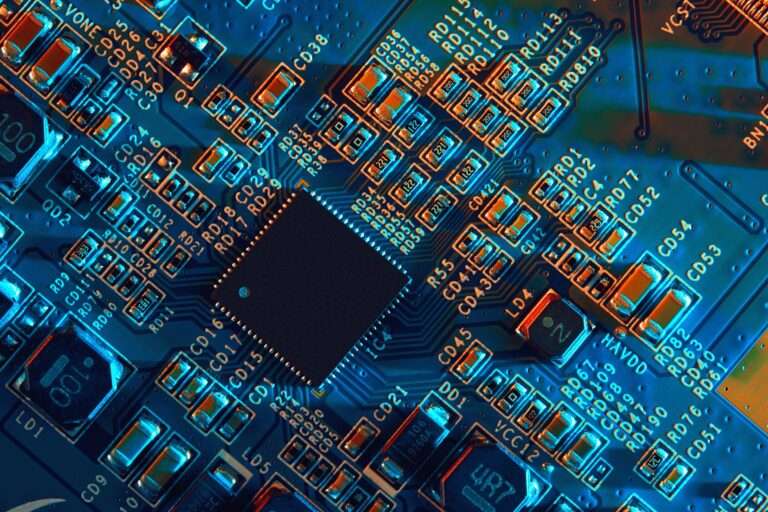

Imagine a small electronics company launching a new product. Their first batch of PCBs arrives with minor defects—just a few solder bridges and misplaced components. However, even these small errors lead to delays, customer dissatisfaction, and increased costs. Now, picture a large-scale manufacturer facing the challenge of producing thousands of flawless PCBs daily. How do they ensure quality control? The answer lies in Automated Optical Inspection (AOI).

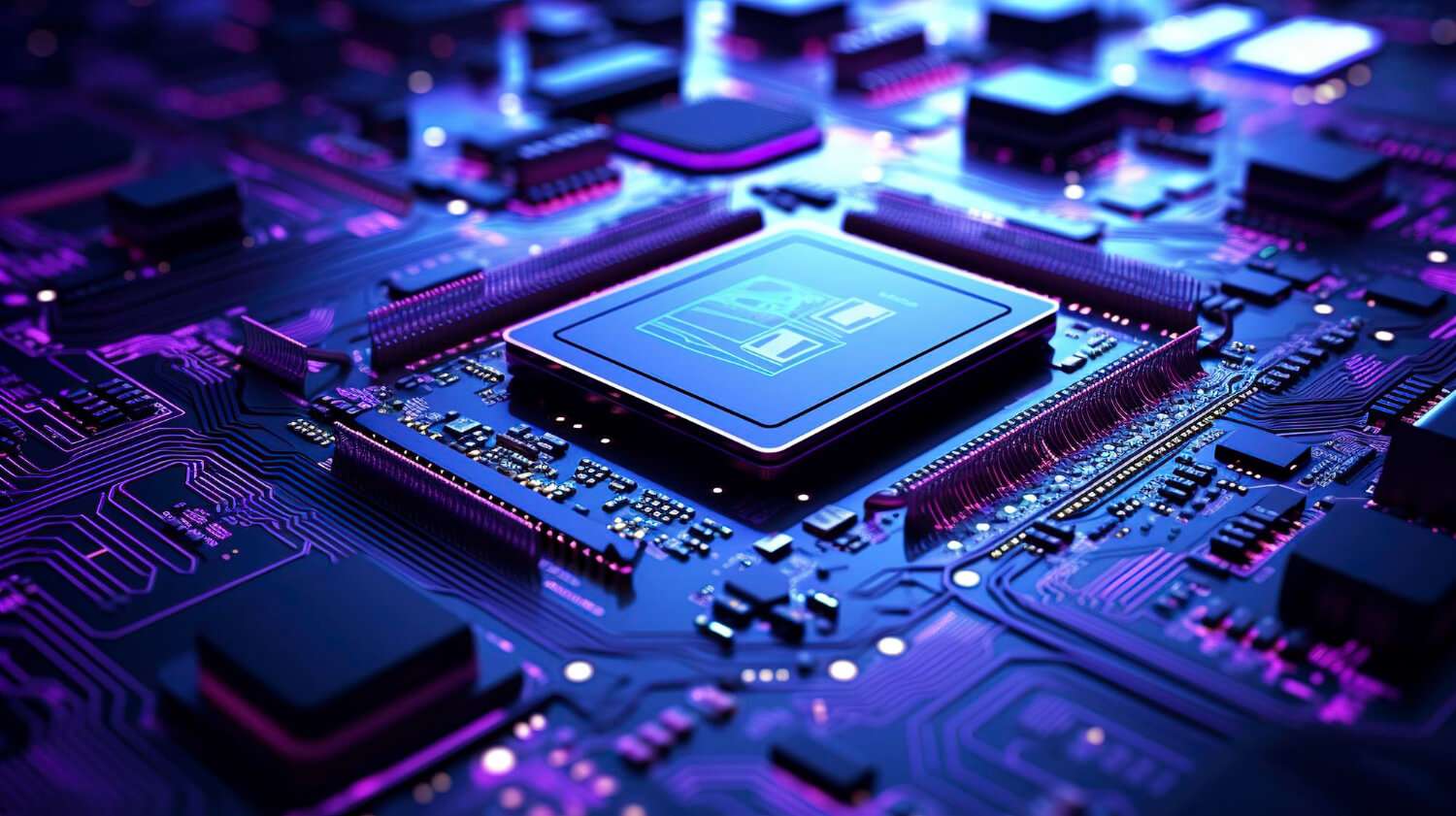

AOI plays a vital role in modern PCB assembly, offering significant benefits but also presenting challenges. It combines high-speed, high-precision visual inspection to identify defects, ensuring that PCBs meet stringent quality standards.

Re-engineering is no longer just a technical exercise; it has evolved into a strategic weapon for companies looking to enhance their competitive edge. In this blog, we’ll explore how re-engineering can be leveraged by founders and CxOs to gain valuable competitive insights and make informed decisions that propel their companies forward.

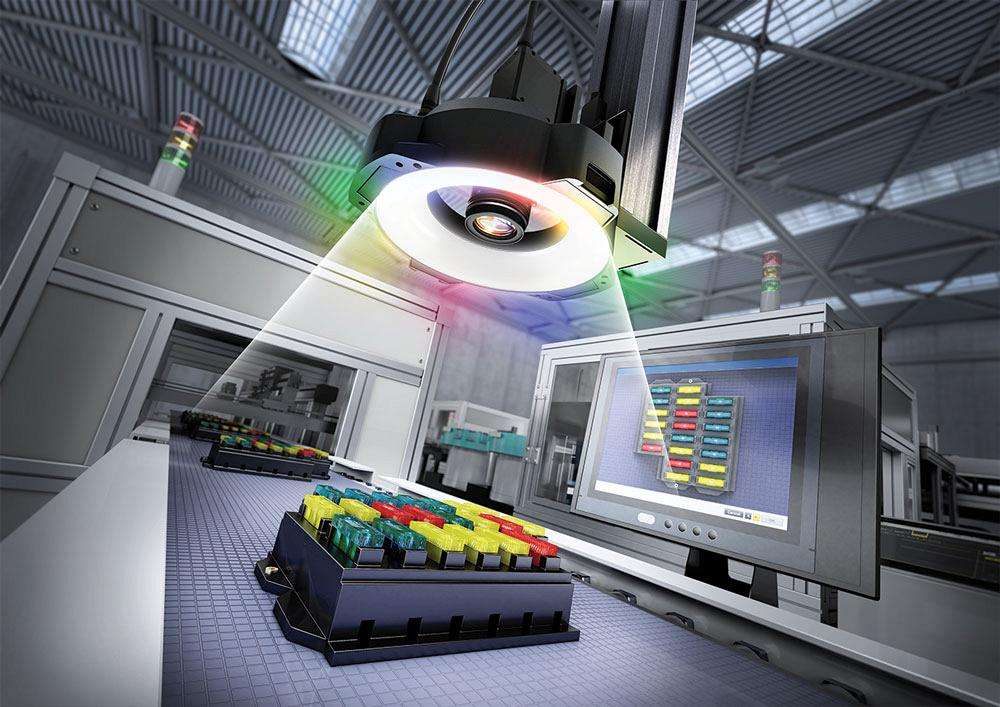

What is Automated Optical Inspection (AOI)?

AOI is a non-contact method that uses cameras and imaging systems to automatically inspect PCB assemblies for defects like misaligned components, solder bridges, or missing parts. It replaces manual inspection, which is prone to human error, with a high-speed, accurate alternative that detects even the smallest anomalies.

Benefits of AOI in PCB Assembly

- Increased Accuracy and Speed

AOI systems quickly inspect thousands of components, ensuring that each meets the required standards. This leads to higher accuracy, reducing costly errors. - Early Defect Detection

AOI identifies issues at an early stage in the assembly process. Detecting errors early minimizes rework costs and prevents defective products from reaching customers. - Enhanced Product Quality

By ensuring that PCBs are free of defects, AOI improves overall product quality, reducing failure rates and enhancing customer satisfaction. - Scalability for Large-Scale Production

Whether you’re a small business or a large manufacturer, AOI is scalable and can handle high-volume production without compromising on quality. - Data-Driven Insights

AOI systems provide detailed reports on defects, helping manufacturers identify trends and optimize production processes.

Challenges of AOI in PCB Assembly

- High Initial Investment

Implementing AOI systems requires a significant upfront investment, particularly for small businesses with limited budgets. - Complex Programming for New Designs

AOI machines need to be programmed with specific parameters for each new design, which can be time-consuming and challenging. - Limitations in Detecting Certain Defects

AOI excels at detecting visual defects, but it may struggle with issues like poor solder joints that aren’t visible on the surface. - Dependence on Operator Expertise

While AOI automates inspection, it still requires skilled operators to set up, maintain, and interpret the system’s output.

AOI technology offers immense benefits for improving the quality and efficiency of PCB assembly, whether for small-scale or high-volume production. While it does present challenges like high costs and programming complexity, its ability to detect defects early and provide detailed insights makes it an invaluable tool for manufacturers. For businesses looking to enhance their PCB production, incorporating AOI can drive growth and increase product reliability.

Reach out to Ark Circuitry for customized solutions that integrate cutting-edge AOI technology into your PCB assembly processes.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!