Why do PCB manufacturers encourage customers to opt for inspection or to run tests on the PCB? Is it really necessary? How do you avoid the hassle of reworking your product? What are the different tests available? Read this post for information.

Why is an inspection/test required?

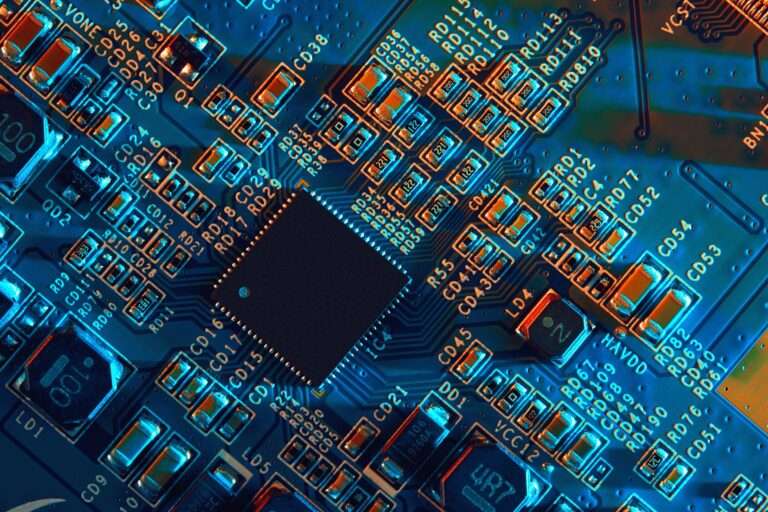

Before the device or system leaves the manufacturing unit a thorough inspection of the PCB mitigates problems in a manufactured product. This helps companies cut down expenses and valuable resources. Sometimes even as simple as solder flux can interfere with the functionality of the PCB and using a non-clean low-residue solder paste is suggested.

What are the different tests available?

There are 3 widely used tests to check the functionality, durability and accuracy of the system : automated optical inspection, X-ray Inspection and burn-in test.

Automated Optical Inspection (AOI)

The AOI uses cameras to capture pictures of the PCB and then compares them with detailed schematics to check errors. when capturing pictures, light is focused from different angles on the board. The images are put together to create a full profile of the board. This system helps in the early detection of nodules, scratches on the board, incomplete or thinning solder, open circuits, missing components and short circuits.

Relying on cameras, the AOI is limited to what is visually detected and is unable to inspect hidden connections, especially in multi-layer boards. Moreover, as external light is used, there could be errors during inspection due to the emerging shadows. Hence, depending on the complexity of the board manufacturers use a combination of inspections to ascertain faults or errors in a board.

X-ray Inspection (AXI)

For boards that are tightly packed with several components (especially small ones) and for multi-layer boards, AOI inspection might not be a suitable test. AOI only detects errors visually from the surface in comparison to X-ray inspection which provides better clarity and inspects the PCB in detail.

Besides, X-ray passes directly through objects and does not need external light as required in AOI. Furthermore, it helps detect issues by examining the board thoroughly as it goes beyond just the surface.

However, this method also has its limitations. The process is extremely time-consuming and setting up an X-ray inspection system is expensive. AXI requires an experienced operator to use the machine which is also an added expense. This leads to exploring the third option, the burn-in test.

Burn-in Test

A burn-in test can enable the early detection of potential problems and helps keep the cost of testing and replacing parts at the lowest. In electronic devices, a burn-in test can determine the maximum temperature it can sustain.

A burn-in may also be a part of routine maintenance or repair. The malfunction might not be straightforward until the hardware is warmed/cooled to a certain temperature or checked for humidity as a factor. Tests under these various environmental parameters could aid in diagnosing the problem and fixing it.

The burn-in test can be performed for an entire system or individual components. The system is operated for extended hours or extreme working conditions to check its functionality and reliability.

Identifying defects at an early stage of the manufacturing process is the most practical way of reducing costs and allows errors to be rectified.

At Ark Circuitry we use high-quality components to ensure the proper functioning of a PCB. We also encourage customers to opt for testing as it is not only important to check the functionality of the product but also to avoid danger when used in highly sensitive applications.

Ark Circuitry Ventures Is An EMS Provider And Specialise In Providing End-To-End Services That Can Be Tailor-Made To Meet Your Requirements.

Let’s talk for more information.

Call us on: +91 91764 18660

Mails us at: arkcircuitry@gmail.com

Visit us at: https://arkcircuits.com/