How can you upgrade an existing product based on technological advancements or specific needs? Do you want to develop a customized product with high standards while remaining cost-effective?

We’re here to help! Ark Circuitry is an Electronic Manufacturing Service Provider, highly adept in design, assembly and manufacturing of printed circuit boards (PCB). Apart from several services we provide, our forte also lies in Reverse Engineering of Existing designs or boards of products. This is possible by our team of well trained engineers with exceptional expertise over two decades.

Reverse Engineering:

Reverse engineering in electronics is the art of meticulously analyzing the design, components, and functionality of an existing product to create a replica, with the aim of enhancing features, reducing cost, and improving durability. By examining each layer and component, engineers gain valuable insights that enable them to enhance the functionality and performance of the final product.

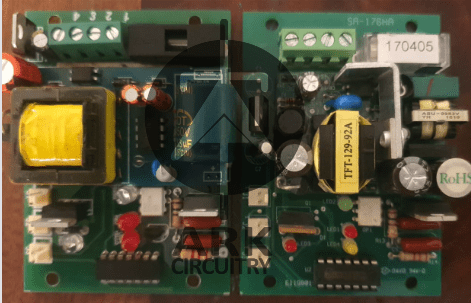

To elucidate, let’s take you through a project we delivered at Ark Circuitry:

UNDERGROUND METRO DAMPER CONTROL SYSTEM:

Any underground metro station across the world is installed with a ventilation exit system. The trains running underground require flushing out large amounts of air which is built due to the trains operating at high speeds inside the tunnels. Therefore, to regulate air pressure and effectively expel excess air, an underground air escape system is essential. This system is managed through the use of large tunnels built at the train stations. These tunnels have open /close dampers, which are operated by high-capacity motors and brakes. We were required to reverse engineer the existing board due to constant failure on the power supply section, high cost implications and import restrictions.

REASONS FOR REVERSE ENGINEERING THE BOARD:

At Ark Circuitry, our customers mostly opt for reverse engineering due to the factors: frequent failure of the actual product, components of the product that are not locally available, to manufacture boards of high quality and for customized products and extended service. The imported boards might require remodeling or redesigned to include better features.

STEPS OF REVERSE ENGINEERING A BOARD:

1. EXAMINING THE ACTUAL PRODUCT:

This is the first step to understand the existing product. At Ark Circuitry, we would require clients to permit us to visit the site for larger product(s)/ installations or provide us with a working model of the existing product itself. We assure our clients that confidentiality will be maintained at all times which times require us to sign a NDA.

2. ANALYSIS OF THE BOARD OR PRODUCT:

- This stage may involve identifying the existing problem in the board and determining to take further action in order to improve the functionality.

- Analyze the circuits, components and ideate changes that needs to be made to include features or upgrade(s) to the product

3. IDENTIFICATION OF THE PROBLEM AND AVAILABILITY OF COMPONENTS

Identifying the key components of the existing control board is the crucial step in reverse engineering and involves sourcing these components locally. In this project, to improve the life of the board we suggested replacing the entire power section of the board.

4. CHOOSING THE TYPE (Analog or Digital):

Firstly, the engineers determine whether the control board is of type analog or digital. Boards utilizing analog circuits tend to be larger in size, prompting the use of digital circuits which replace bulky components with integrated circuits (ICs) to reduce overall size. Sometimes, digital ICs are employed as a means of increasing complexity and deterring reverse engineering attempts by other companies. In the damper control system, we swiftly analyzed that the circuit uses a microcontroller for operations and we replaced the existing one with a high temperature IC for durability.

5. REDUCING COST AND INCREASING EFFECTIVENESS:

We were able to enhance the performance of the damper control board,increase product lifetime, resolve the power supply issue to avoid overheating, and also reduce the cost of manufacturing these boards. We reconstructed the entire circuit to precisely match the 1:1 ratio.

As a result, we were able to reduce the cost by 1/5th of what was previously being paid to the original manufacturer they were importing from.

Ark Circuitry provides an unlimited warranty period of 2 years for reverse engineered boards whereas the original manufacturer was providing only 3 months.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to upgrade or fix issues in your product?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!