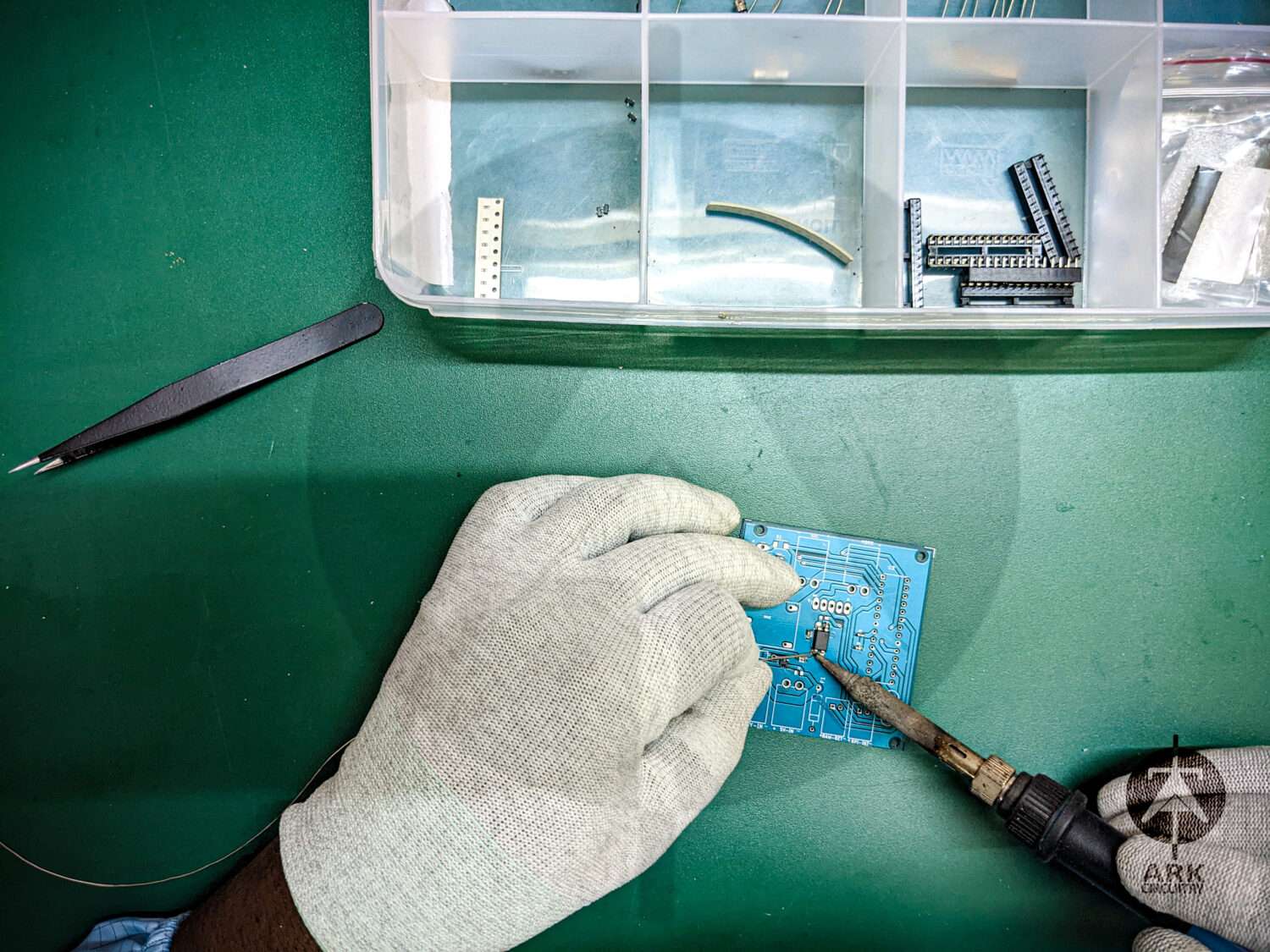

product Prototyping

Product prototyping

We help you conceptualise an idea, explore your concept and provide solutions by testing and proving the concept to deliver a product that can be presented to your customer/investor to begin the manufacturing process. Our R&D team specialises in testing and evaluating PCB design and its performance, to create an accurate and functional prototype of your PCB assembly design. The prototype is put through rigorous testing to determine its durability, functionality and long-lasting reliability. Before beginning the manufacturing process, it is imperative for PCBA prototyping to ensure the production of a fully functional product.

Prototyping allows you or your stakeholder to interact with the product, understand its functionalities, evaluate room for improvements, detect design alterations, generate new ideas or arrive at solutions if required.

When you partner with us, we provide you with quality assurance, a streamlined manufacturing process and a reliable product. Our quick response and effective communication will ensure a smooth manufacturing process. For high-volume production, detecting issues and fixing them before investing and manufacturing the product helps cut costs exponentially. The prototype is put through part-fit, temperature humidity, thermal shock and vibration testing.

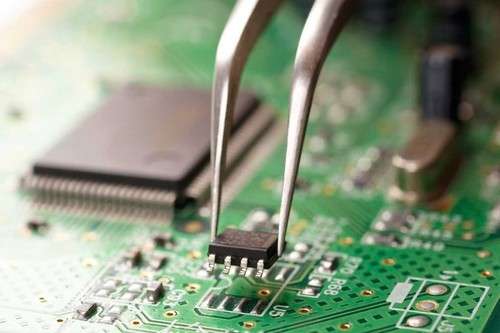

our prototyping capabilities

- PCB design and development

- Component sourcing

- In-house Firmware development (Microcontroller, microprocessor, Kernel

- In-house Software and mobile application development

- Turnkey assembly

- Assembly Testing

- Environmental Testing

- Part-fit Testing

- Cable Harness Assembly

- Tailored Full System Integration (Box Build Assembly)

- Anodizing, powder coating, coating & finishing

Are you looking for flexible options?

build your best connection with us

be the first to get the latest news from ark circuitry!

Please Enter Your Email To Subscribe