SMT PCB Assembly

Maximize Tech, Compact in Size

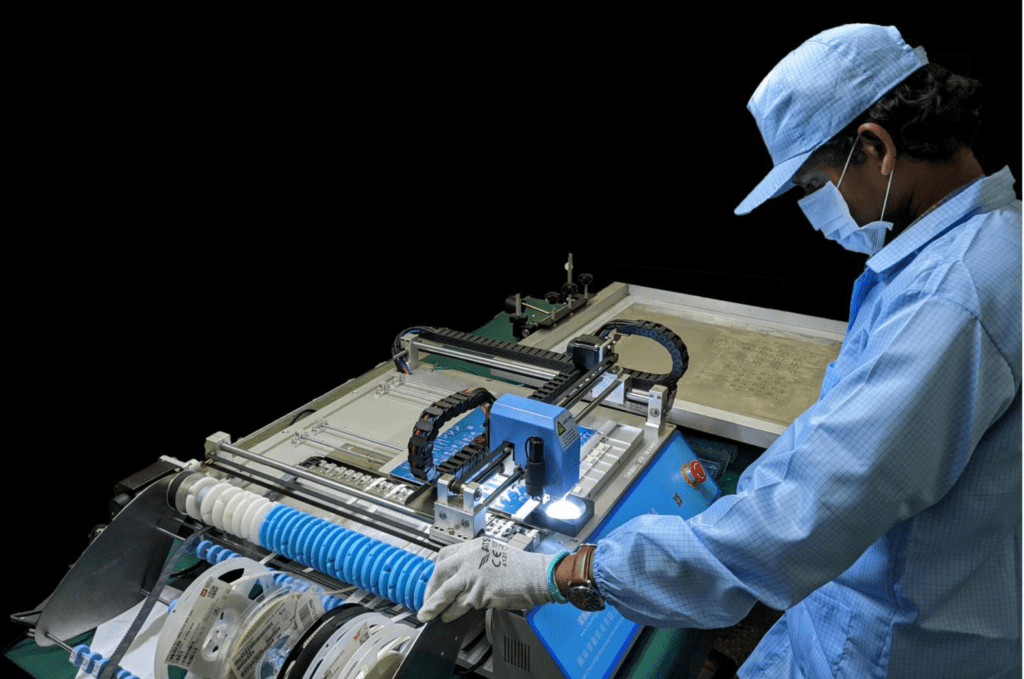

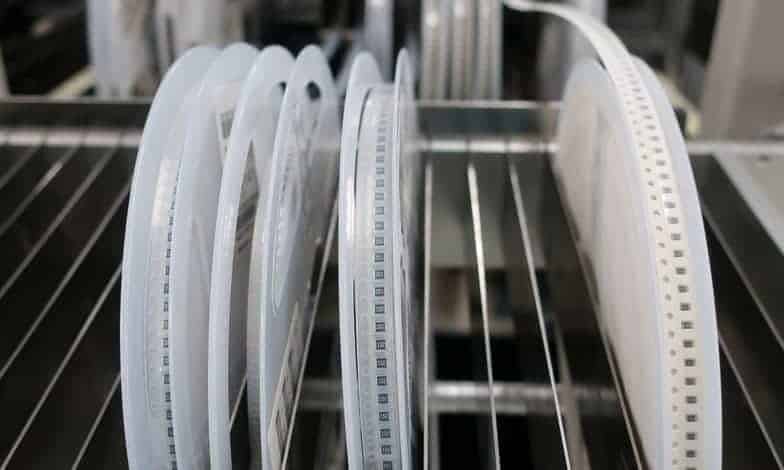

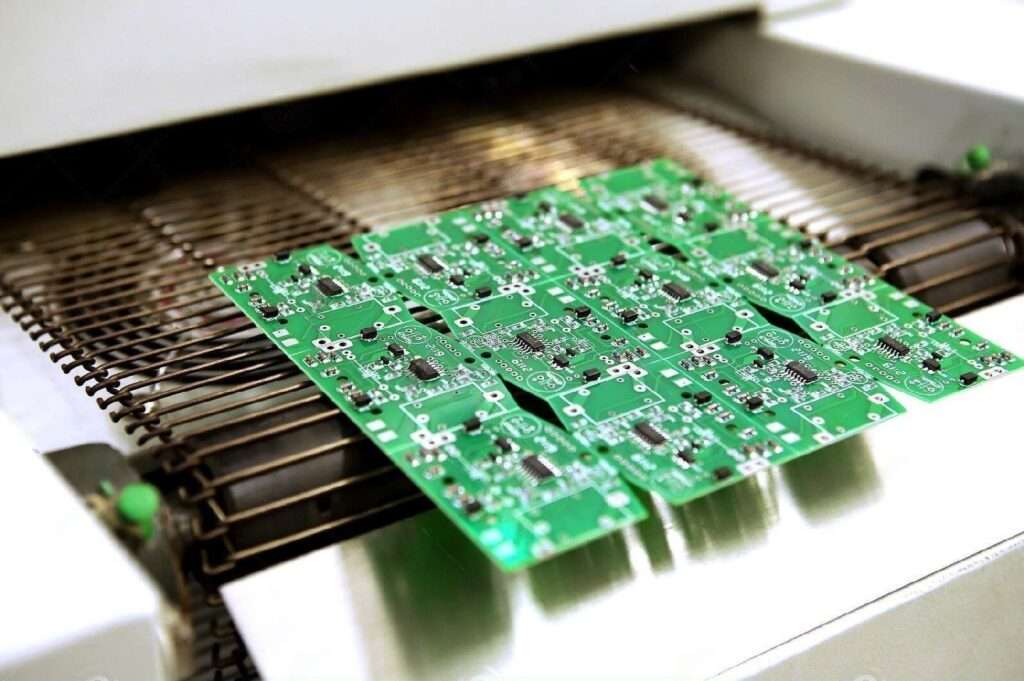

In order to allow manufacturers to use small components with higher density of connections and superior component density on a single board, Surface Mount Technology is the most flexible assembly process would be the best choice. Component placement can be single-sided, double-sided or multi-tier and does not require drilling through the board, allowing for a more streamlined and automated-friendly process.

The advantage of surface mount boards are that they are faster and easier to assemble, making them cost-effective to manufacture. SMT assemblies are better able to handle conditions such as shock or vibrations, are known for their stronger mechanical performance and provide high-frequency performance.

With years of experience in SMT assembly, we provide services for customers over a wide range of applications. Ark Circuitry has the skills and resources to design and process any PCB assembly project that would meet your requirements. We can deliver the best PCBA depending on your need for small or large production run or provide you with the assistance for prototyping.

We at Ark Circuitry can meet and exceed industry standard in SMT PCBA with the sophisticated equipment and well qualified and trained engineers. With our automated assembly lines, we are able to streamline the assembly process and manufacture PSBAs that are of superior quality, reliable and cost effective. Partner with us and be ensured to receive the highest level of accuracy for your required quantity of components.

Surface Mount Technology

- Streamlined assembly process and overall production

- Allows for smaller components

- List ItemHigher density of connection

- Stronger reliability

- Improved performance of PCBAs

- Cost-effective manufacturing process

- A more automated process

Are you looking for flexible options?

build your best connection with us

be the first to get the latest news from ark circuitry!

Please Enter Your Email To Subscribe