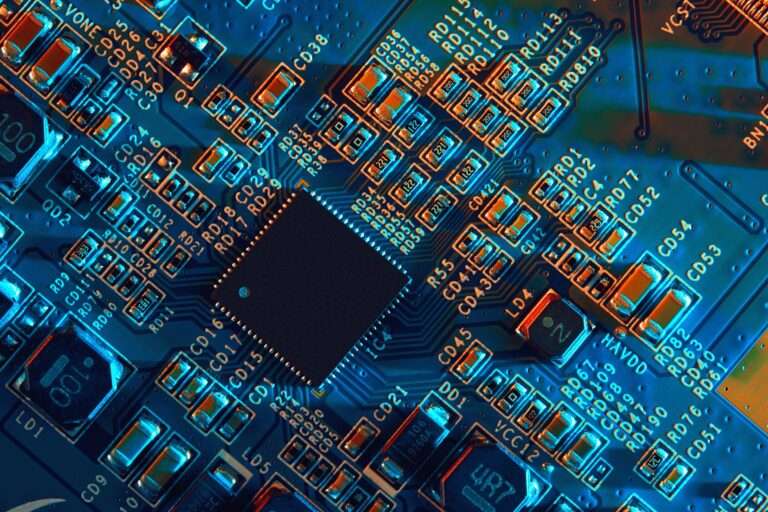

Circuit boards are vital to any electronic device and run many processes depending on the function complexities of the device. There are small but significant measures and steps to follow during manufacturing for a fully functional and reliable PCB.

The functioning of electronic devices relies heavily on their circuit boards. There are steps to be followed and measures to be taken during manufacturing and more so before shipping them. Read more to find out a small but significant step that is essential in the manufacturing process.

How is a Printed Circuit Board contaminated?

During the manufacturing process, the board becomes contaminated during the assembly or exposed to the environment. There could be any type of contamination not limited to fingerprints, residue, moisture, dust, oxides are to be looked out for. The connections and circuits may become affected and lead to corrosion overtime resulting in failures and short circuit. The lifespan of the device is important to its consumers and the PCB is an integral part in the working of the device. Any malfunction may tarnish the reputation of the manufacturer as well as disrupt the functioning of the product.

Why is cleaning the PCB an essential process of assembly?

Once the PCB is assembled it is then cleaned before the inspection. Cleaning is considered an important step in the assembly process. Firstly, any residue or dirt on the board can affect its functioning, like overheating or other issues. Secondly, failure to thoroughly clean a PCB can have effects on the durability, reliability and effectiveness of the device. In other words, the lifespan or longevity of the PCB may be affected. The device needs to be in optimal condition to increase its durability of the device.

PCBs used in sensitive devices or in industries like automotive, military, aerospace or telecommunications must be devoid of potentially any form of pollutant. Even when ‘No residue Flux’ is used, it is still advisable to clean the board and not allow any flux to sit on the board to thereby avoid delamination or poor wetting. It is imperative that the PCB is free of any contaminant before going into the next stage of the manufacturing process or mounting it into an enclosure.

Packaging and delivery

The AOI uses cameras to capture pictures of the PCB and then compares them with detailed schematics to check errors. when capturing pictures, light is focused from different angles on the board. The images are put together to create a full profile of the board. This system helps in the early detection of nodules, scratches on the board, incomplete or thinning solder, open circuits, missing components and short circuits.

Relying on cameras, the AOI is limited to what is visually detected and is unable to inspect hidden connections, especially in multi-layer boards. Moreover, as external light is used, there could be errors during inspection due to the emerging shadows. Hence, depending on the complexity of the board manufacturers use a combination of inspections to ascertain faults or errors in a board.

Safety measures to be followed during cleaning process

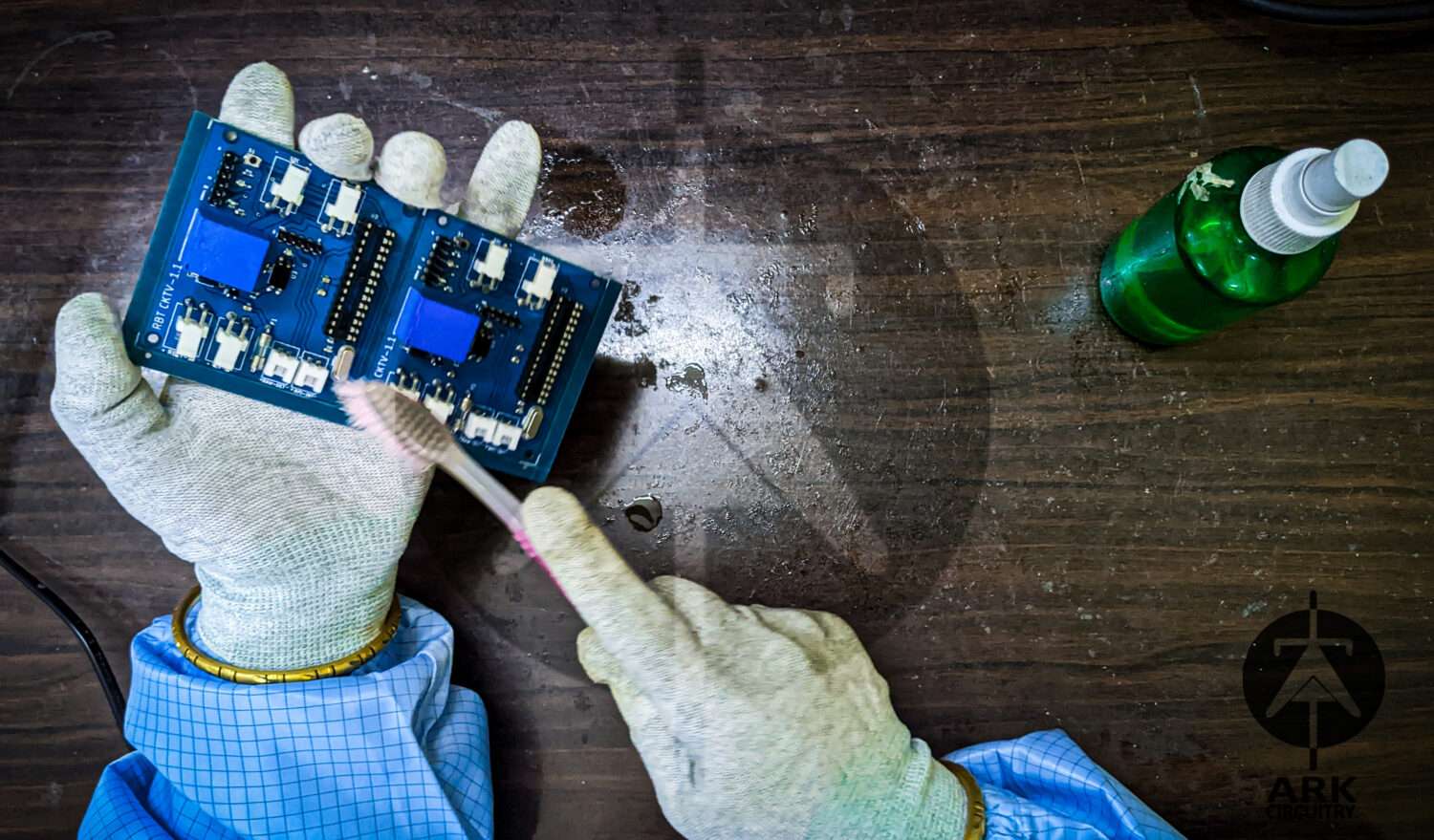

When manually cleaning the PCBA, lint-free cloth or q-tips and Isopropyl alcohol is used. While working with IPA solution, necessary precautions are to be taken while handling it to avoid any potential health hazards.

- Ensure to be seated in a well-ventilated room

- Transfer the IPA solution to a spray bottle

- Use goggles to protect eyes from IPA vapour or splashes

- Wear gloves and protective clothing to avoid skin contact

- Use a face mask to avoid inhaling the vapour

In the event of exposure to IPA solution, the following steps should be taken to prevent serious health hazards:

Eye Contact: Ensure to flush your eyes with water or a saline solution for at least 20 minutes. Follow up with seeking medical attention.

Skin Contact: Remove all clothing that has come in contact with the solution and wash the skin thoroughly with soap and water. If skin irritation or redness occurs, seek medical attention.

Inhalation: The individual must be moved to an outdoor area with fresh air and visit a medical centre to prevent any health hazards.

Ingestion: If the person is conscious, give them about 2 glasses of water to dilute the alcohol. Ensure not to induce vomiting to avoid the risk of the chemical being aspirated into the lungs while vomiting. The person must be taken to a medical centre immediately.

Check out our YouTube video for a quick run-through of the manual cleaning process of a PCBA.

Ark Circuitry Ventures Is An EMS Provider And Specialise In Providing End-To-End Services That Can Be Tailor-Made To Meet Your Requirements.

Let’s talk for more information and discuss your manufacturing needs.

Call us on +91 91764 18660

Mails us at: arkcircuitry@gmail.com

Visit us at: https://arkcircuits.com/