Revolutionizing Connectivity

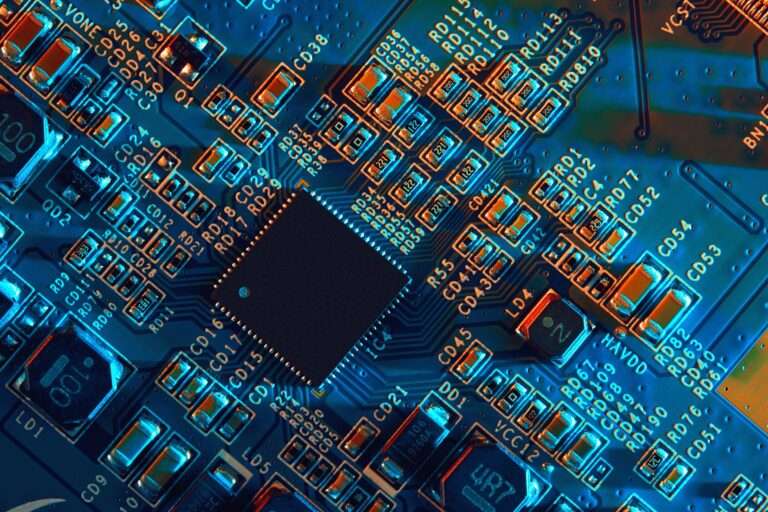

Imagine a cutting-edge smartphone that seamlessly integrates multiple functions into a sleek, compact design. The driving force behind its high performance and efficiency is often hidden from plain sight—High-Density Interconnects (HDI) in its PCB (Printed Circuit Board). As technology continues to advance, HDI PCBs are transforming the landscape of electronics, offering unparalleled benefits in performance and reliability. This blog explores the profound impact of HDI technology on PCB design and how it can elevate your product’s capabilities.

What Are High-Density Interconnects (HDI)?

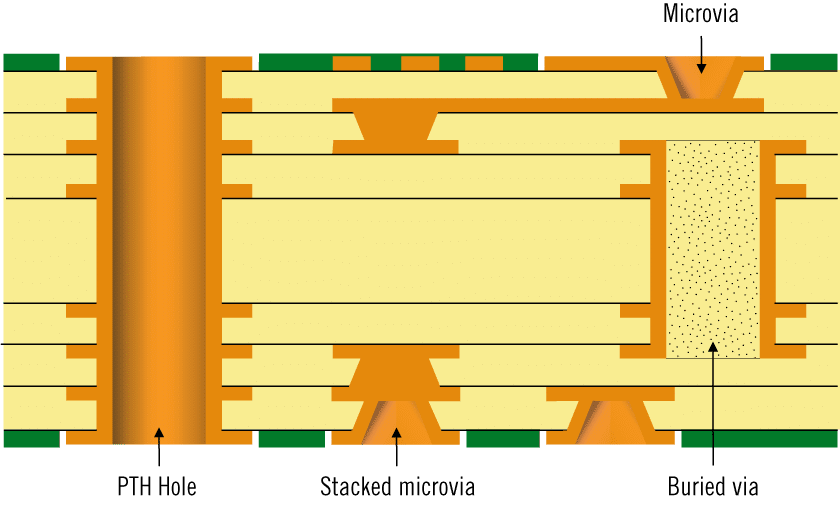

HDI refers to a PCB technology characterized by its use of microvias, fine lines, and high-density circuitry to increase the functionality and reduce the size of PCBs. By incorporating multiple layers of circuitry within a compact space, HDI enables the design of more complex and compact electronic systems.

Advantages of HDI in PCB Design

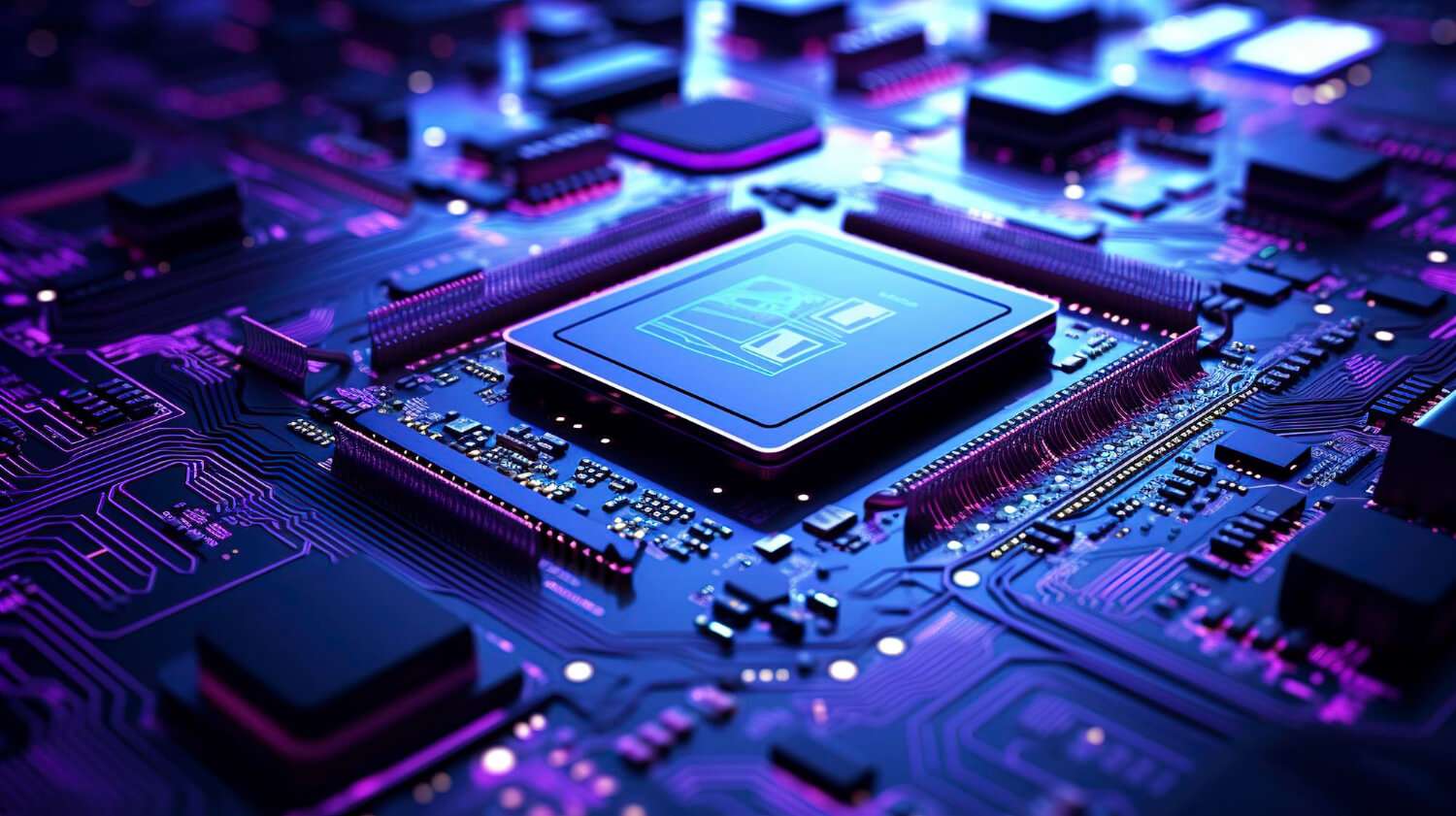

- Enhanced Performance

HDI PCBs offer superior performance due to their ability to handle high-frequency signals with reduced signal degradation. The fine lines and microvias minimize the signal path lengths, leading to faster and more reliable signal transmission. - Compact and Lightweight Design

The use of HDI technology allows for a higher component density, which significantly reduces the size and weight of PCBs. This is crucial for applications requiring miniaturization, such as mobile devices, wearables, and medical equipment. - Improved Thermal Management

High-density interconnects contribute to better thermal management by allowing efficient heat dissipation through the PCB layers. This is essential for maintaining the performance and longevity of electronic components, especially in high-power applications. - Cost Efficiency in the Long Run

While the initial cost of HDI PCBs can be higher due to advanced manufacturing processes, the long-term benefits include reduced material usage, lower assembly costs, and fewer design revisions. The overall cost-efficiency of HDI technology makes it a valuable investment for many businesses. - Design Flexibility

HDI technology provides greater design flexibility by allowing more complex routing and component placement. This adaptability is beneficial for developing innovative products and accommodating advanced features.

Applications of HDI PCBs

- Consumer Electronics: Smartphones, tablets, and wearables leverage HDI for compact and efficient designs.

- Medical Devices: Precision and reliability in medical equipment benefit from the advanced performance of HDI PCBs.

- Automotive Industry: HDI enhances the reliability and functionality of automotive electronics.

- Telecommunications: High-frequency applications in telecommunications benefit from HDI’s superior signal integrity.

Embracing HDI for Competitive Advantage

Incorporating HDI technology into your PCB design can significantly impact your product’s performance, size, and cost-efficiency. As businesses strive for innovation and competitiveness, understanding and leveraging HDI technology becomes essential. Whether you are developing consumer electronics or complex industrial systems, HDI can provide the advanced capabilities you need to stay ahead in the market.

Ready to elevate your PCB design? Contact us today to explore how HDI technology can transform your products.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!