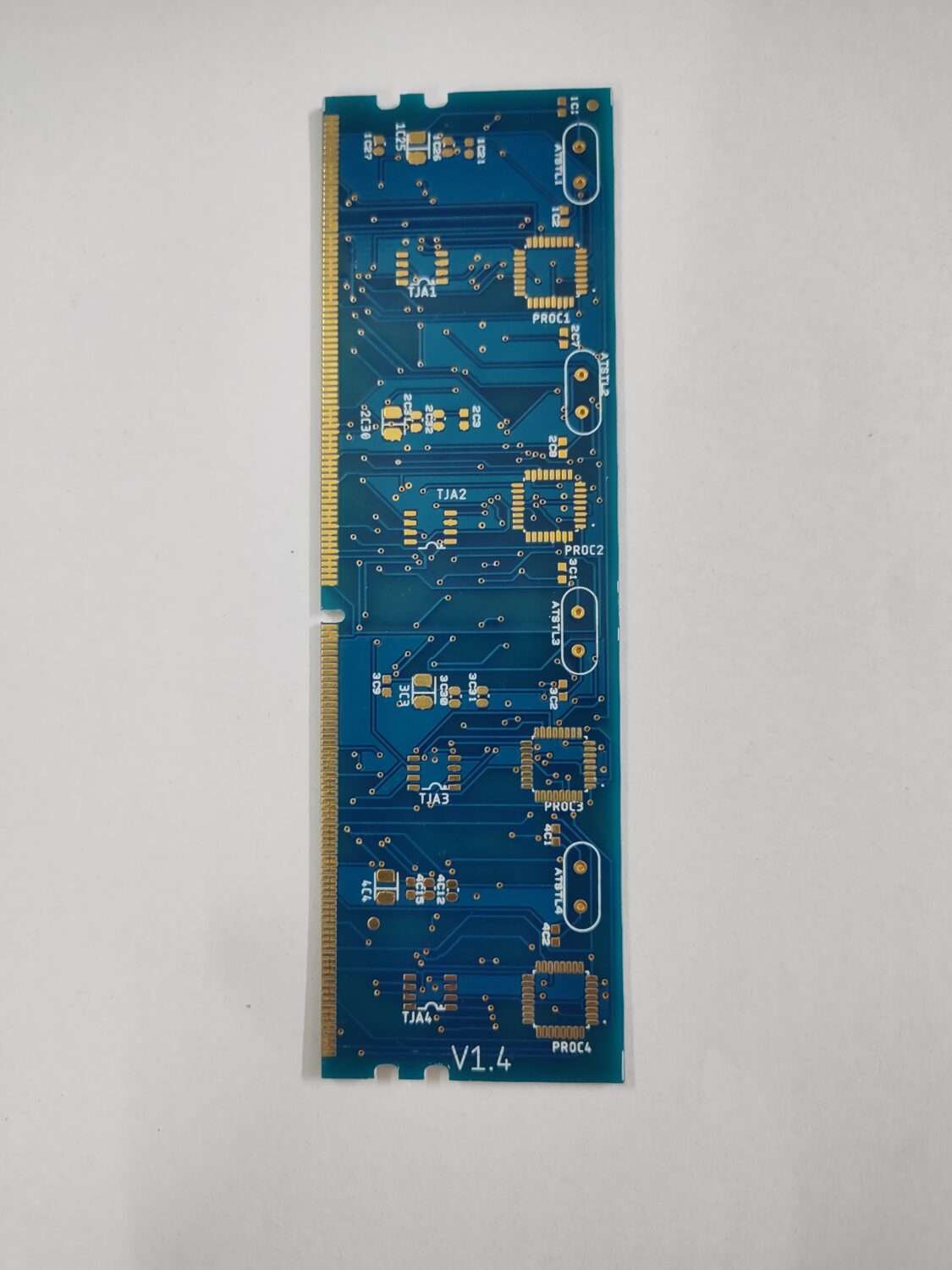

In the rapidly evolving realm of electronics manufacturing, a critical factor that demands utmost attention is the surface finish meticulously applied to printed circuit boards (PCBs). Explore an intriguing article with Ark Circuitry to find out about the surface finish that is widely utilized and safeguards against corrosion and oxidation.

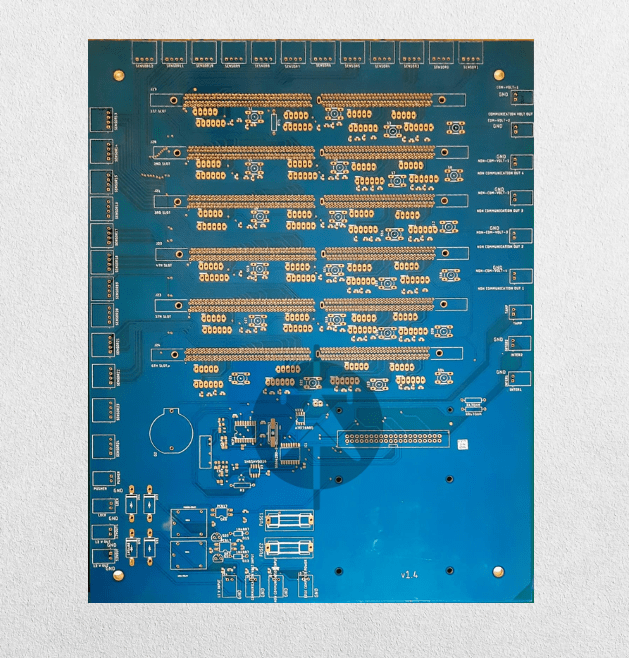

Ark Circuitry Ventures is an Electronic Manufacturing Service provider and PCB manufacturer specialize in providing End-to-End services that can be tailor-made to meet your requirements. We offer a comprehensive range of Surface Mount Technology (SMT) processes to accommodate various production scales. This includes a fully automated SMT process tailored for large volume production and a semi-automated SMT process designed for small run production.

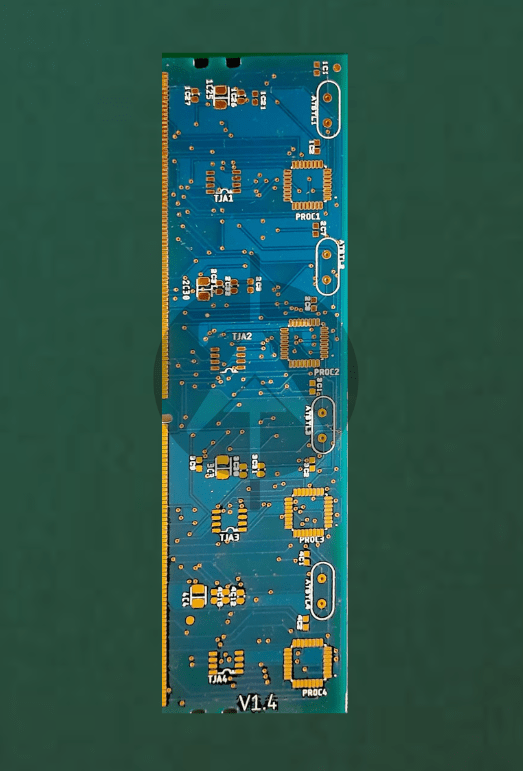

Introduction to ENIG:

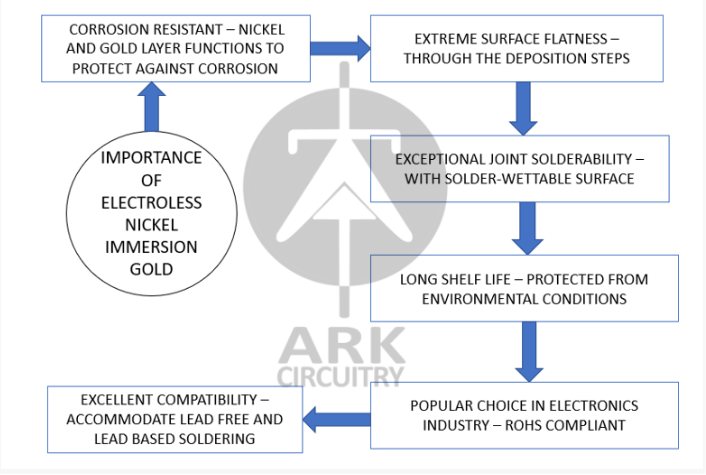

Electroless Nickel Immersion Gold(ENIG) also known as immersion gold, is an unique and precise surface finish process offering an extension of shelf life and high resistance to corrosion. At Ark Circuitry, we aim to ensure customer satisfaction by providing top-notch ENIG surface finish on PCBs according to their specific requirements.

How do we do ENIG at Ark Circuitry:

- Firstly, with Ark circuitry, we prioritize ensuring a clean surface for the PCB board, accomplished by meticulously cleaning away dirt using a suitable abrasive material.

- Furthermore, we engage in precise etching procedure by using an acid solution to remove unwanted copper, thus, ensuring optimal surface smoothness and uniformity on the board.

- At Ark Circuitry, our skilled team of engineers expertly submerge the printed circuit board (PCB) into an electroless nickel solution, wherein a reducing agent and a source of nickel ions are present, forming a delicate nickel coating on the exposed copper surfaces of the PCB. And the board is rinsed to eliminate excess nickel from the surface. The nickel acts as a protective barrier on the copper pads of the PCB board.

- Our engineers immerse the nickel-plated board into a solution containing gold salts. Thus, the ENIG plating consists of a layer of gold which protects the nickel thus offering low resistance.

- Again, the gold-plated PCB undergoes a thorough cleaning process followed by drying, effectively eliminating the residual chemicals .

- Finally, the PCB board is ready for testing and assembly. Applying the ENIG process, successfully prevents corrosion and oxidation, resulting in better electron conductivity and durable finish.

Assessing The Thickness Of Nickel And Gold in ENIG:

The thickness of nickel can range from 4 to 7 µm, while gold thickness can range from 0.05 to 0.23 µm.

Regarding gold thickness specifically:

Besides, for standard PCB and flex PCB applications, we recommend a range of 1-3 micro inches However, for advanced PCBs, we prioritize a slightly higher range of 2-3 micro inches.

Pragmatic benefits of ENIG coating:

ENIG coating is utilized in wire bonding applications to establish dependable interconnections between integrated circuits and other components.

Moreover, the gold layer present in ENIG aids in gold wire bonding, which is commonly employed in specialized electronic applications, such as high-frequency devices.

Our clients:

Our specialization lies in the diverse application of ENIG across various sectors, encompassing defense, medical-grade boards, automotive, and aerospace industries.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!