Deciphering PCB Vias

Delve into the realm of PCB vias! This blog post dissects blind vias and through-hole vias, unravelling their differences, applications, advantages, and disadvantages.

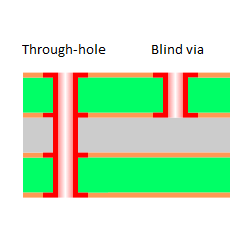

Vias are important conduits in printed circuit boards (PCBs) that establish connections between different layers. Blind vias and through-hole vias are essential elements with unique characteristics.

Blind Vias: Unlocking the Essentials

Blind vias are used to connect the outer layers of a PCB to one or more inner layers. These vias are especially useful for high-density designs and compact electronic devices.

Applications of Blind Vias:

- High-density interconnects in smartphones, tablets, and miniaturized electronics.

- Complex designs demanding intricate routing solutions.

Advantages of Blind Vias:

- Increased routing density, allowing for more compact designs.

- Improved signal integrity due to shorter connections.

- Reduced layer count, hence lower manufacturing costs.

Disadvantages of Blind Vias:

- Limited to specific layer connections.

- Demands precise drilling during fabrication, potentially increasing manufacturing complexity.

Through-Hole Vias: The Traditional Workhorse

Through-hole vias traverse the entire PCB, connecting all layers from top to bottom. While more conventional, they may not suit highly compact designs.

Applications of Through-Hole Vias:

- General PCB designs where reliability is crucial.

- Industries requiring robust and well-connected layers, such as automotive and aerospace.

Advantages of Through-Hole Vias:

- Enhanced reliability due to complete board penetration.

- Suitable for multilayer PCBs, ensuring stronger connections.

Disadvantages of Through-Hole Vias:

- Consumes significant space in dense designs.

- Complex manufacturing processes, potentially raise overall costs.

Blind Vias vs. Through-Hole Vias

Differences | Blind Vias | Through-Hole Vias |

Penetration | Penetrates only a portion of PCB layers | Traverses the entire PCB, top to bottom |

Layer Connectivity | Connects outer layers to inner layers | Connects all layers, offering full access |

Space Utilization | Offers increased routing density | Consumes more space, less ideal for density |

Complexity | Requires precise drilling for fabrication | Less complex manufacturing process |

Cost | Can reduce layer count, lowering costs | May increase manufacturing costs |

Application Suitability | Ideal for high-density designs | Suitable for general PCBs and robust connections |

Navigating the Viaduct

The decision to use either blind or through-hole vias depends on specific design requirements. Understanding their applications, trade-offs, and unique functionalities is crucial during PCB design and fabrication processes.

Get in Touch with Us

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!