Electronics equipment, consumer electronics, and the growing demand for innovative technological advancements paves way for manufacturers to capitalise on the opportunities. With the sophistication in manufacturing technology, the growing complexity of electronic devices is both time-consuming and expensive. This requires manufacturers to engage with experienced solution partners who offer industry expertise.

The advent of digital computers

Clearly, the digital computer era and its subsequent progress around the 1990s have increased the usage of electronics in mainstream industries. Electronics have become indispensable in the global industrial sector. The increase in demand for consumer electronics, healthcare equipment, aviation, automotive industries, industrial automation, defence, and network and communication equipment has provided business opportunities to several EMS providers (Electronics Manufacturing Service Providers). These manufacturers provide a series of valued added services such as manufacturing, procurement, design & development and distribution for electronic product manufacturers.

The Shift in modern technology

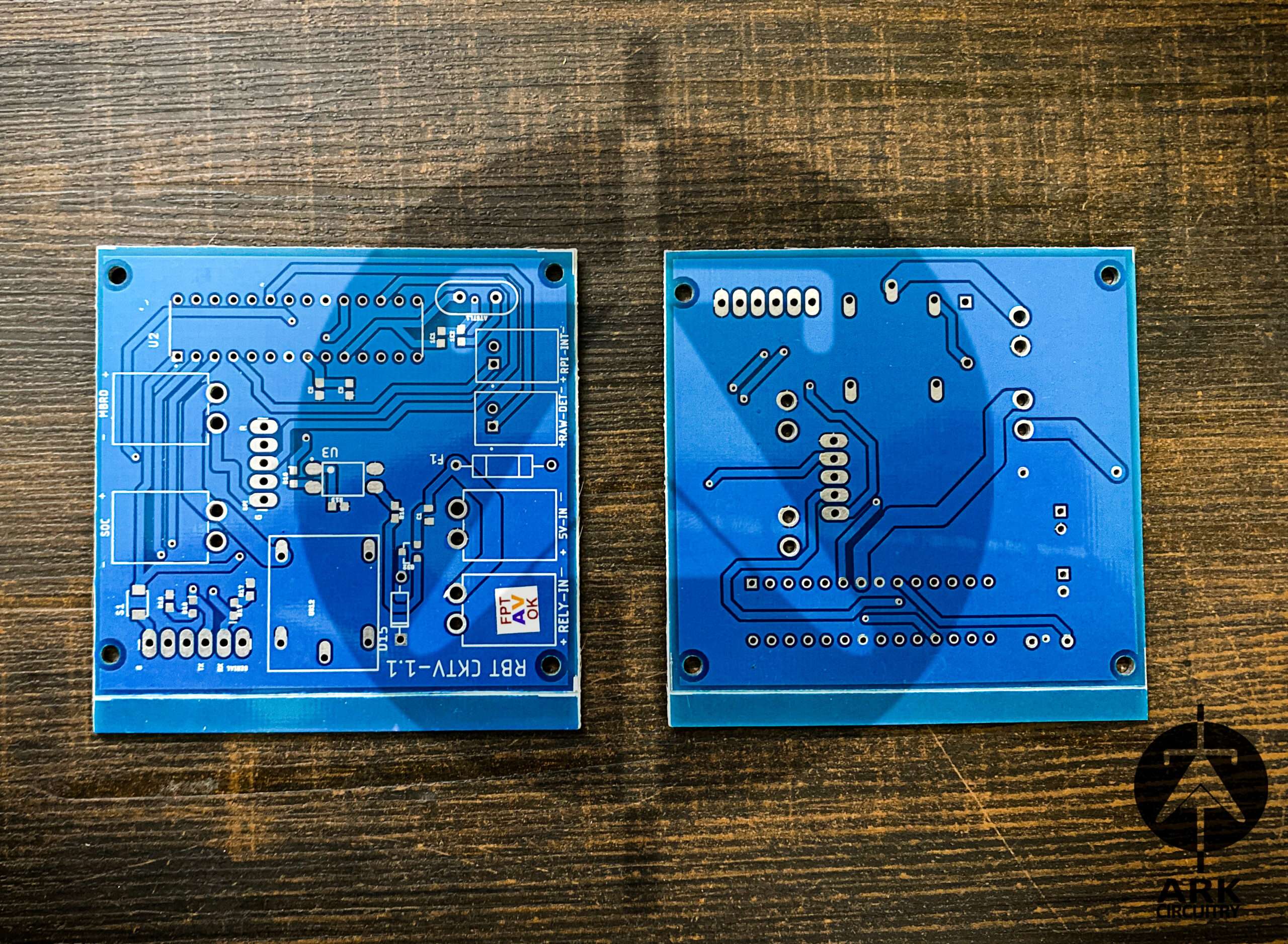

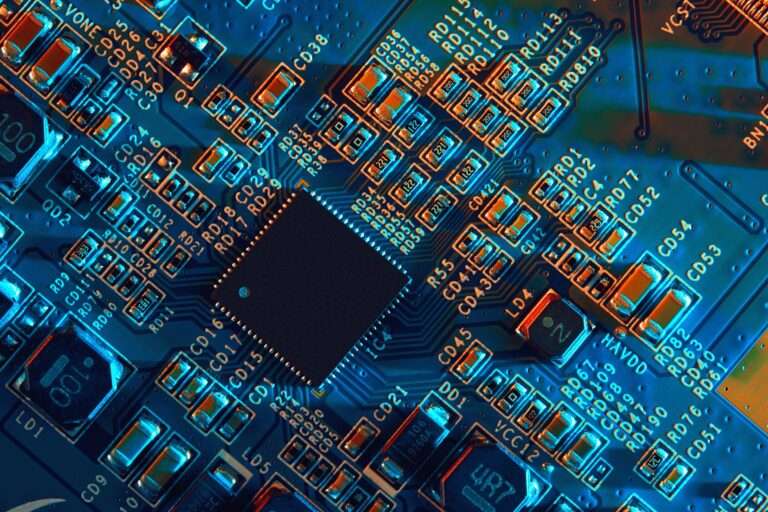

Electronic devices have seen several cycles of change and the miniaturisation of devices associated with the development and technological advancement has been evident with time. The capabilities have become vast, more economical than the previous generations, easily available and diverse over the decades. The printed board circuits have become small in size and more powerful in function.

The role of EMS in manufacturing

EMS providers have become important partners of manufacturers in accelerating the manufacturing process. EMS can include design, assembly, manufacturing, testing of electronic components, and procurement for manufacturers. They can be contracted during any step of the production process. Depending on individual requirements they can provide simple design solutions prior to the development, sourcing or procurement of components, assembly, testing of electronics components or products, manufacturing components, printed circuit boards and assembly of products or prototypes.

Emerging Technologies have revolutionised the Manufacturing Processes

The evolution of technology has shrunk the size of components and PCBs have become progressively small in size. Electronic processes have become more complex such as multiple layers, smaller boards, delicate components and parts, precise placements and other such concerns. Manufacturers are expected to speed up the process without cutting costs or jeopardising the quality of products while adapting to newer and unfamiliar technologies.

Furthermore, the production processes have become more streamlined with innovative and sophisticated technological solutions. The consistent and rapid development of IoT has enhanced the efficiency of the production process. Industrial automation or robotics in the manufacturing industries have revolutionised the production process both in terms of speed and precision. For example, the process of hand soldering components on PCBs is being replaced by Surface Mount Technology (SMT) that enables seamless assembly of SMD (surface mount devices) on boards. A fundamental revolution has also taken place in the machine learning space aka AI or artificial intelligence. It is a transformative technology in the way machines function and communicates.

Without a doubt, the surge in demand has also reflected in EMS companies transcending from just providing manufacturing services to now offering end-to-end services to customers to support them during manufacturing. These services may include guidance in the certification process, collaborating during ideation, maintenance systems, new product design and development, hardware and system architecture implementations, supplier management, etc. to name a few.

Strategic transitions with growth in Electronics demands

Particularly in the manufacturing space, there have been several collaborations, mergers, negotiations and other relevant agreements among OEMs, ODMs, EMS providers and customers to adapt to the changes that have been taking place. It is not just outsourcing a specific or all processes of manufacturing, companies have also begun to hire production lines for manufacturing. To boost production, several strategies like expanding software functionality, streamlining manufacturing processes through digitisation, automated assembly lines, etc are becoming prominent.

Supply chain management- The Key to manufacturing

The revolution in technology is to speed up the processes without hastening the system. Nevertheless, the challenges in the supply chain continue to cause limitations to the EMS which hampers the speed of innovation and technology adoption. This disrupts delivery schedules, costs, logistics and production planning. Thus an EMS provider building a network and supply chain relationships highly impact keeping deliveries on time.

Ark Circuitry, a leading player in SMT manufacturing, is designed and capable Of catering to a global customer base. Powerful, integrated software and hardware systems are essential to electronics manufacturing services. We ensure to facilitate better flexibility, productivity, and quality across applications.

Let’s talk for more information.

Call us on: +91 91764 18660

Mails us at: arkcircuitry@gmail.com

Visit us at: https://arkcircuits.com/