PCB production is a fascinating and intricate process that lies at the core of modern electronics manufacturing. From concept to final product, the journey of a printed circuit board involves multiple stages and precise techniques. In this blog post, we will delve into the PCB production process, exploring each step and highlighting the importance of precision and quality.

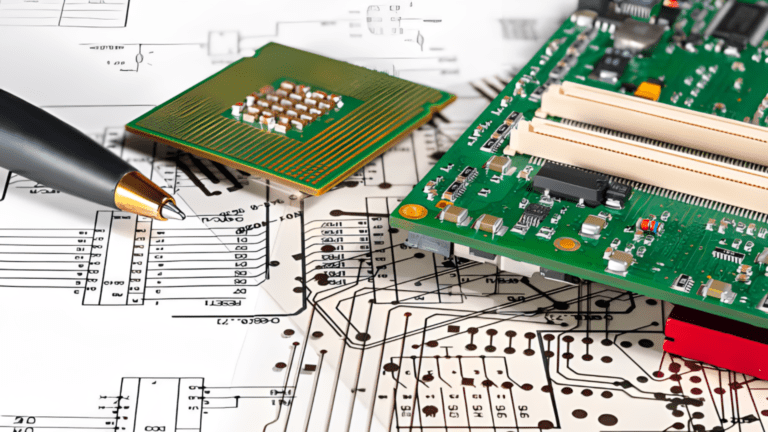

Design & Prototyping

The PCB production process begins with the design phase, where engineers conceptualize the circuit layout and component placement using specialized software. This stage is crucial for ensuring optimal functionality and efficiency of the final board. Once the design is finalized, a prototype is created to test the circuit’s performance and identify any potential issues or improvements. PCB prototyping allows for iterative refinement before moving to mass production.

Material Selection and Preparation

Selecting the right materials is paramount in PCB production to ensure durability, conductivity, and thermal stability. Common materials used include fiberglass-reinforced epoxy resin (FR-4) for the board substrate and copper for the conductive traces. The materials undergo rigorous testing and preparation, including cutting, drilling, and cleaning, to meet industry standards and specifications.

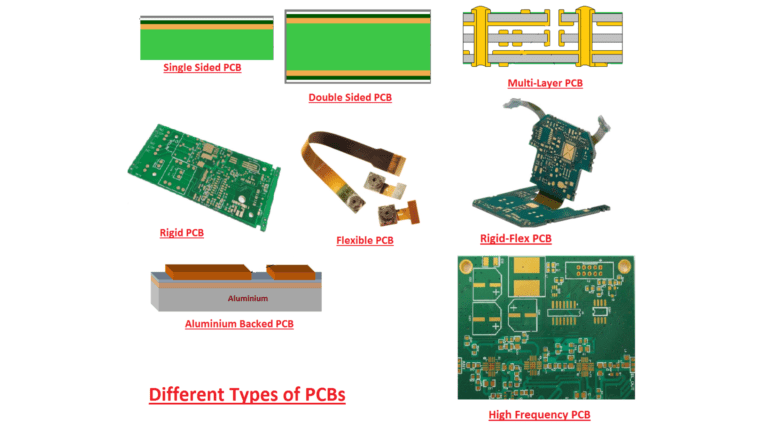

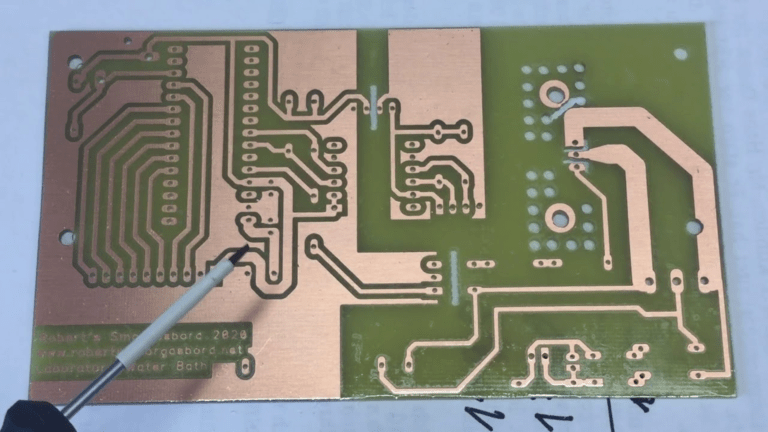

Etching and Layering

The next step in PCB production is etching, where a chemical process removes excess copper from the board surface, leaving behind the desired conductive traces. This process is guided by the circuit design created earlier. For multilayer PCBs, multiple layers of substrate and conductive traces are laminated together, creating intricate pathways for electronic signals. Each layer is etched and aligned precisely to ensure proper connectivity.

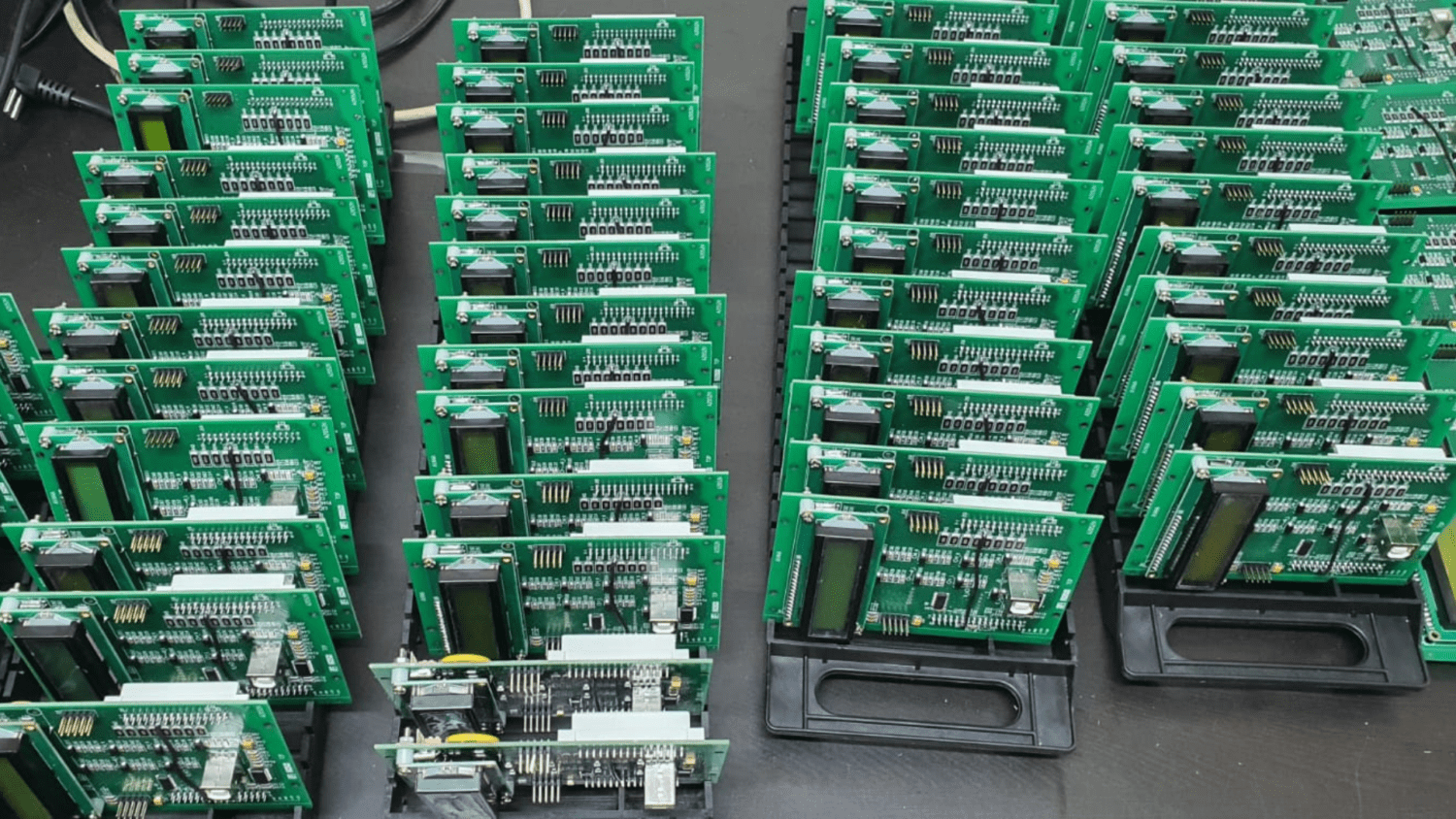

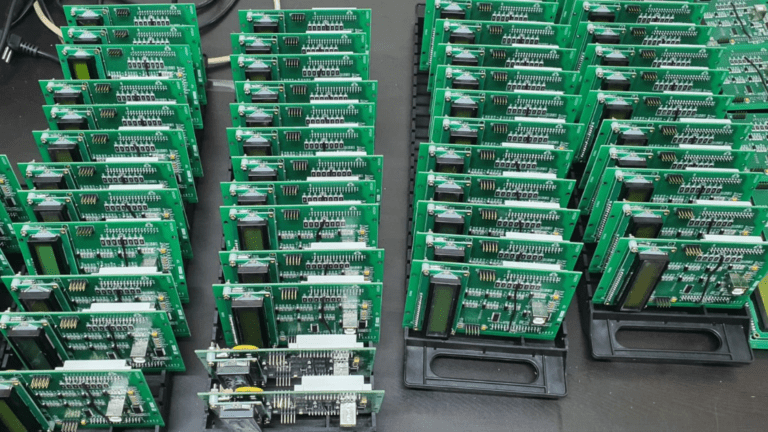

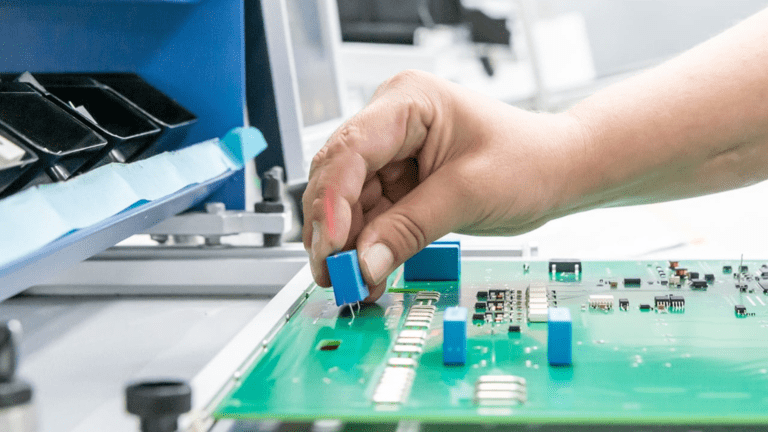

Assembly and Testing

Once the PCB layers are etched and prepared, the assembly phase begins. Components such as resistors, capacitors, integrated circuits, and connectors are soldered onto the board according to the design specifications. Advanced technologies like surface mount technology (SMT) and automated assembly equipment streamline this process, improving accuracy and efficiency. After assembly, the PCB undergoes rigorous testing, including electrical continuity tests, functionality checks, and quality assurance measures to identify and rectify any defects.

The PCB production process is a complex yet meticulously executed journey that brings electronic devices to life. From initial design and prototyping to material selection, etching, assembly, and testing, each step contributes to the final product’s functionality and reliability. At Ark Circuitry, we pride ourselves on our expertise and precision in PCB production, ensuring top-notch quality for our clients’ electronic needs.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!