Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, offering numerous advantages over the traditional Through-Hole technology. This blog post will delve into the various aspects that make SMT a superior choice, providing a comprehensive comparative analysis. From design efficiency to performance and cost-effectiveness, we will explore why SMT has become the preferred method for modern PCB manufacturing.

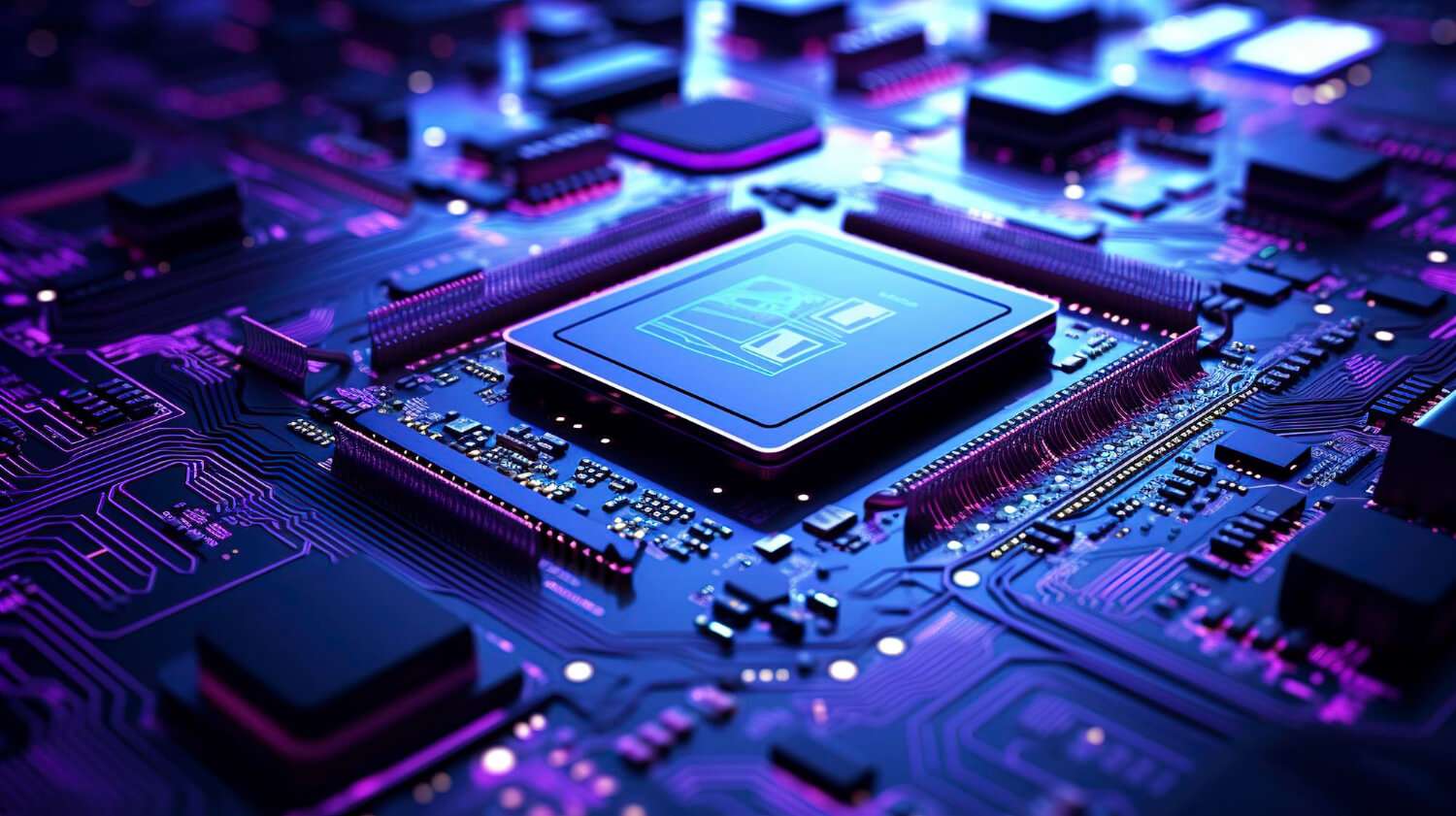

The Rise of SMT

Surface Mount Technology has transformed the way electronic components are mounted onto printed circuit boards (PCBs). Unlike Through-Hole technology, which involves inserting component leads into drilled holes on the PCB, SMT mounts components directly onto the surface. This innovation has paved the way for more compact, reliable, and cost-effective electronic devices.

Design Efficiency: Compact and Lightweight

One of the most significant advantages of Surface Mount Technology is its contribution to design efficiency. SMT components are smaller and lighter compared to Through-Hole components. This reduction in size allows for more components to be placed on a single PCB, enabling the creation of compact and lightweight electronic devices. Consequently, this is particularly beneficial for modern gadgets such as smartphones, tablets, and wearable devices, where space is at a premium.

Enhanced Performance: Speed and Reliability

Transitioning from Through-Hole to Surface Mount Technology significantly enhances the performance of electronic devices. SMT components can be placed on both sides of the PCB, maximizing the use of available space and enabling more complex circuit designs. Additionally, the shorter lead lengths in SMT reduce signal path lengths, minimizing signal interference and improving overall performance. As a result, SMT provides higher speed and reliability, which is crucial for high-frequency and high-performance applications.

Cost-Effectiveness: Reduced Manufacturing Costs

Surface Mount Technology offers considerable cost savings in the manufacturing process. SMT allows for automated assembly, which reduces labor costs and increases production efficiency. The smaller size of SMT components also means less material usage, leading to lower component costs. Furthermore, the ability to place more components on a single PCB reduces the number of boards needed, resulting in significant cost savings, especially in high-volume production.

Improved Durability: Better Heat Dissipation and Stress Resistance

Another critical advantage of SMT is its improved durability. SMT components are soldered directly onto the PCB, providing better mechanical support and reducing the risk of physical damage. This method also ensures better heat dissipation, as the components are in direct contact with the PCB, which acts as a heat sink. Additionally, SMT components are less prone to stress and vibration, making them ideal for applications in harsh environments, such as automotive and aerospace industries.

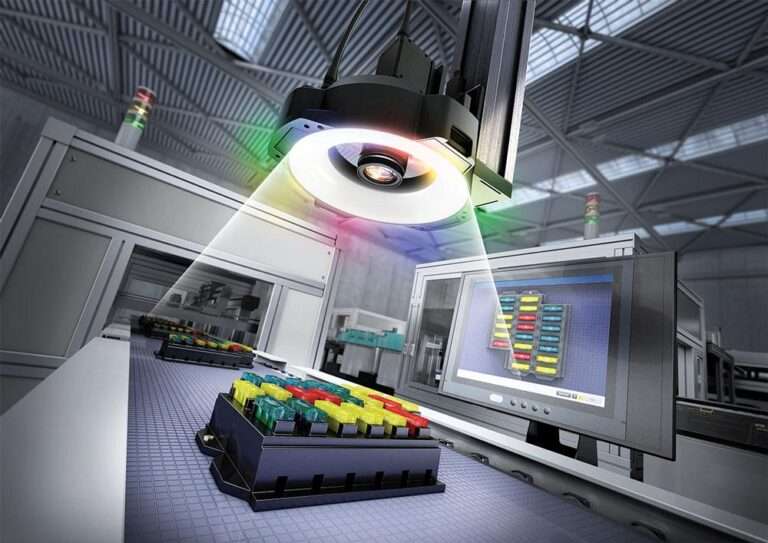

Flexibility and Versatility: Meeting Modern Demands

Surface Mount Technology offers unparalleled flexibility and versatility in PCB design and assembly. SMT supports a wide range of component types and sizes, enabling designers to create innovative and sophisticated electronic products. The ability to place components on both sides of the PCB further enhances design flexibility. Moreover, SMT is compatible with advanced manufacturing techniques, such as pick-and-place machines and reflow soldering, allowing for rapid and precise assembly.

Conclusion: The Future of PCB Manufacturing

In conclusion, Surface Mount Technology has proven to be superior to Through-Hole technology in various aspects, including design efficiency, performance, cost-effectiveness, durability, and flexibility. As the demand for smaller, faster, and more reliable electronic devices continues to grow, SMT will remain at the forefront of PCB manufacturing. Embracing SMT is essential for staying competitive in the ever-evolving electronics industry.

Ready to upgrade your PCB manufacturing process? Contact us today to learn more about how Surface Mount Technology can enhance your products and streamline your production.

Our services cater to clients interested in manufacturing products in India, with a focus on reducing costs while enhancing both the quality and efficiency of their production process.

Looking to design or fabricate a PCB?

Talk to us to know more.

Mail us on arkcircuits@gmail.com

Call us at +91 9176418660.

Ark Circuitry is an integrated electronics design assembly and mass manufacturing service provider renowned for crafting end-to-end services that accurately align with your unique requirements. With our team of seasoned engineers committed to excellence, we provide reliable and high quality services!